When embarking on a concrete project, whether it’s a simple patio, a robust driveway, or a sprawling foundation, the right contractor can make all the difference. Navigating the world of concrete work can feel daunting, filled with technical jargon and an array of choices. To help demystify this process, we present a complete checklist designed to guide you from the initial consultation to the final pour. This article will walk you through the essential steps and considerations you should expect when hiring a concrete contractor,illuminating the pathway to achieving a accomplished,high-quality outcome. With this checklist, you’ll be well-equipped to engage confidently with contractors and ensure your project aligns with your vision. Join us as we explore what you can expect from start to finish, turning your concrete dreams into solid realities.

Understanding Your Project Scope and Requirements

When embarking on a concrete project, comprehending the scope and requirements is essential to ensuring a successful outcome. A clear definition of the projectS extent will help you and your contractor align your expectations. Start by identifying the core components, such as:

- Project Size: Determine the total area that needs concrete.

- Type of Concrete: Choose between options like decorative, stamped, or standard concrete.

- Purpose: Understand whether it’s for a driveway, patio, or foundation.

- Budget: Establish a realistic financial plan that accommodates contingencies.

Once the initial details are in place, it’s crucial to delve deeper into specific requirements that may influence your project timeline and execution. Establishing a timeline for each phase can keep everything on track. Consider factors like:

- Site Readiness: What needs to be done before the concrete is poured?

- Permits and Regulations: Are there local codes to adhere to?

- Weather Conditions: How might this affect the pouring and curing processes?

- Accessibility: Can heavy machinery easily access the project site?

Essential Preparations Before Breaking Ground

Before you embark on your concrete project, there are several key preparations necessary to ensure a smooth process. Site evaluation is critical; assess the land for any potential hazards, including underground utilities or unstable soil, which could complicate the excavation process. additionally, consider the local weather conditions and timing, as adverse weather can adversely affect the curing process of concrete. Make sure that you have a comprehensive plan that includes your project’s timeline and milestones, which will help in keeping all parties accountable.

Obtaining the proper permits is another vital step you cannot overlook. Check with local authorities to identify the necessary permits for construction and ensure compliance with zoning regulations. Furthermore, it’s essential to gather a reliable team of contractors, including laborers, equipment suppliers, and specialists who can assist with various aspects of the project.The following table summarizes the essential preparations needed before breaking ground:

| Preparation Step | Description |

|---|---|

| Site Evaluation | Assess land for hazards and soil stability. |

| Weather Consideration | Check local forecasts for optimal timing. |

| Permits | ensure all required permits are obtained. |

| Team Assembly | Gather contractors and specialists for support. |

Key Stages of the Concrete Pouring Process

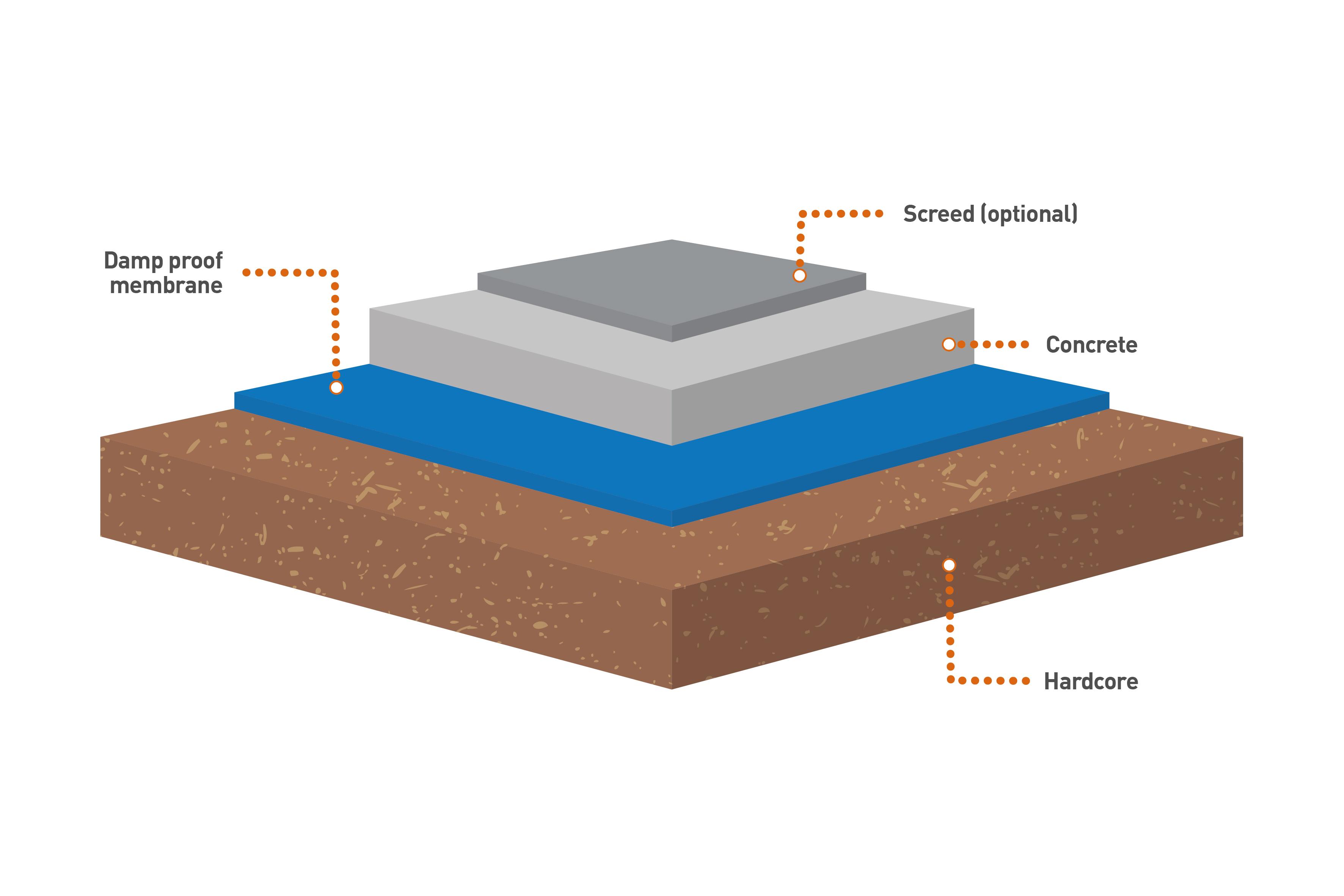

The concrete pouring process is a critical phase in any construction project,requiring meticulous planning and execution.After preparing the site and constructing the necessary formwork,it’s vital to conduct a thorough inspection to ensure everything is ready for the pour. Once the team confirms the formwork integrity, the mix design should be prepared, balancing the right materials and proportions to achieve the desired strength and durability. Timing is essential here, as the concrete must be poured before it begins to set.

during the actual pouring phase, the concrete trucks will arrive on-site, bringing the freshly mixed concrete.The contractors will begin pouring the concrete carefully into the forms, utilizing techniques such as vibration to eliminate air pockets and enhance compaction. as the pour progresses, workers will use tools like screeds to level the surface and ensure an even distribution of the concrete. Once poured, the concrete needs to be adequately cured to achieve its optimal strength, often involving covering it with plastic sheeting or applying curing compounds to maintain moisture levels.

Quality Control Measures to Ensure Success

To achieve successful outcomes in concrete projects, implementing rigorous quality control measures is vital. This involves establishing a systematic process to monitor various aspects throughout the project lifecycle. Key strategies include conducting regular inspections and testing to ensure materials meet specified standards. Here are some critical quality control checkpoints:

- Material Inspection: Confirming the quality of cement, aggregates, and additives before use.

- Mix Design Verification: Ensuring the concrete mix adheres to the required specifications.

- Slump Test: Measuring the consistency of freshly mixed concrete to achieve the desired workability.

- Curing Conditions: Monitoring environmental factors to prevent premature drying or exposure to adverse conditions.

Along with these initial measures,regular assessments during the curing process are essential. Employing testing methods such as compressive strength tests at various curing intervals can provide valuable feedback on your project’s progression. Utilizing technology for real-time monitoring can further enhance quality assurance efforts. In the table below, you can find some recommended testing intervals in relation to curing days:

| Curing Days | Recommended Tests |

|---|---|

| 1-3 Days | Initial Slump Test, Temperature Checks |

| 7 Days | Compression Strength Test |

| 14 Days | Surface Hardness Assessment |

| 28 Days | Final Compression Strength Test |

Final Steps and Ongoing Maintenance Tips

After the concrete pouring process is complete, there are essential steps to ensure the longevity and durability of your installation. Begin with allowing the concrete to cure properly; this typically takes about 28 days, during which it should remain moist. to aid in this process, consider using plastic sheeting or wet burlap to help retain moisture. Additionally, avoid placing heavy objects on the concrete or exposing it to extreme temperatures instantly after pouring. Some key maintenance actions include:

- Regularly check for cracks and surface damage.

- Seal the concrete every few years to prevent moisture infiltration.

- Clear debris and dirt buildup to avoid stains and wear.

- Repair any visible cracks promptly to prevent further deterioration.

When it comes to ongoing maintenance,performing seasonal checks can be very beneficial. This ensures any issues are caught early, perhaps saving you time and money in repairs down the line. You might want to establish a simple maintenance schedule, such as:

| Season | Maintenance Task |

|---|---|

| Spring | Inspect for cracks, and clear debris. |

| Summer | apply sealant if necessary. |

| Fall | Prepare for winter; clear leaves and snow. |

| Winter | Monitor for damage from de-icing agents. |

Q&A

Concrete Contractor Checklist: What to Expect from Start to Finish

Q1: What is the first step in selecting a concrete contractor?

A: The journey begins with research! Look for local contractors with positive reviews and a solid track record. Ask friends or family for recommendations, scour online platforms, and check for necessary licenses and insurance. A well-reviewed contractor sets the stage for a smooth project.Q2: How should I prepare for the initial meeting with a contractor?

A: Come equipped with your vision! Gather inspiration images, make a list of questions, and outline your project’s scope.Think about the concrete type you desire—stamped, colored, or standard—and be ready to discuss your budget and timeline expectations.

Q3: What major factors should influence my project estimate?

A: Several elements come into play including project size,concrete type,site accessibility,and local labor costs. You should also consider additional work like excavation or grading, as these can impact the overall price. A reputable contractor will provide clear,detailed,and transparent estimates.

Q4: What should I expect during the concrete pouring phase?

A: This is where your vision starts to take shape! Initially, the contractor will prepare the site, including setting forms and ensuring the subgrade is properly compacted.When it’s time to pour, expect a flurry of activity: mixing the concrete, pouring it into forms, leveling, and finally finishing techniques being applied—like troweling or stamping.

Q5: How long will the concrete take to cure, and what does that involve?

A: Concrete typically takes about 28 days to reach full strength, but it’s usable much sooner—often within a week.The curing process involves maintaining moisture to aid in hardening. Your contractor will likely apply curing compounds or cover the surface with wet burlap to ensure optimum conditions.

Q6: What ongoing maintenance should I plan for?

A: To keep your concrete in top shape, regular maintenance is key! this can include sealing the surface every few years, fixing minor cracks promptly, and ensuring proper drainage to protect against water pooling. Your contractor may offer guidance on maintaining the longevity of your concrete.

Q7: How should I handle any issues that arise post-project?

A: Dialogue is crucial! If you encounter issues, reach out to your contractor immediately with a clear description of the concern.A professional contractor should be willing to address any problems that arise within a reasonable timeframe.

Q8: Once the project is completed, what follow-up should I expect from the contractor?

A: Many reputable contractors will check in after the project completion to ensure your satisfaction. This is a good time to discuss fading or other concerns, and they may offer maintenance tips or schedule follow-up inspections to ensure durability.

Q9: What’s the best advice for a smooth concrete project?

A: Clear communication is paramount! Be open about your expectations, be receptive to recommendations from your contractor, and maintain frequent check-ins throughout the process. This builds trust and helps keep your project on track!

navigating a concrete project can be a rewarding experience when you’re well-informed and prepared. By following this checklist and engaging with your contractor meaningfully,you can ensure a successful outcome from start to finish!

In Summary

As you embark on your next concrete project,whether it’s a new driveway,patio,or foundation,remember that preparation is key. The contractor checklist we’ve discussed serves not just as a roadmap through the complexities of the concrete installation process, but as a guiding hand in ensuring quality and peace of mind. From the initial consultation to the final sealing, each phase is crucial to achieving results that withstand the test of time.

By understanding what to expect at every step, and knowing the right questions to ask, you empower yourself to collaborate effectively with your concrete contractor. This partnership is vital to transforming your vision into a lasting reality. Keep this checklist handy, and approach your project with confidence, clarity, and purpose.

In the world of concrete, every detail matters—so take the time to carefully consider each element. With the right preparation and a reputable contractor by your side, your project will not only meet your expectations but exceed them, paving the way for success and satisfaction. Happy building!